Recently, many non-woven manufacturers have come to our company to inquire about non-woven cutting. There are several issues they care about. Whether the vibrating knife cutting machine can cut non-woven fabrics, whether it can cut multiple layers, and whether the speed is fast....

However, the non-woven samples we have seen are made of bags and protective clothing. The thickness of each non-woven fabric is different, so the thickness and speed of cutting with the vibrating knife are also different.

Let me tell you about the relevant knowledge of non-woven fabrics, and interspersed with some information on cutting non-woven fabrics with vibrating knife cutting machines.

what is non-woven?

NonWovenFabric is also called Nonwovencloth

Non-woven fabric (non-woven fabric) is a kind of fabric that does not require spinning or weaving. It only orients or randomly arranges textile staple fibers or filaments to form a web structure, and then uses mechanical, thermal bonding or chemical reinforced by other methods.

Simply put: it is not interwoven and braided by yarns one by one, but the fibers are directly bonded together by physical methods, so when you get the sticky weight in your clothes , you will find that it is impossible to extract a single thread.

Characteristics of non-woven fabrics

Advantage

Lightweight

Using polypropylene resin as the main raw material, the specific gravity is only 0.9, only three-fifths of cotton, with fluffy and good hand feeling.

soft

Composed of fine fibers (2-3D) light point-like hot melt bonding molding. The finished product is moderately soft and comfortable.

Water repellent, breathable

Polypropylene chips do not absorb water, have zero moisture content, and the finished product has good water repellency. It is composed of 100% fiber, which is porous and has good air permeability. It is easy to keep the cloth dry and easy to wash.

Non-toxic and non-irritating

The product is produced with FDA-compliant food-grade raw materials, without other chemical ingredients, with stable performance, non-toxic, no peculiar smell, and does not irritate the skin.

Chemical resistance

Polypropylene is a chemically inert substance, not moth-eaten, and can isolate the erosion of bacteria and insects in the liquid.

Antibacterial

The product is water-repellent, not moldy, and can isolate the erosion of bacteria and insects in the liquid, and is not moldy.

Good physical properties

It is made of polypropylene spun directly into a mesh and thermally bonded. The strength of the product is better than that of ordinary staple fiber products. The strength is non-directional, and the vertical and horizontal strengths are similar.

Environmental friendly

In terms of environmental protection, the raw material of most of the non-woven fabrics used is polypropylene, while the raw material of plastic bags is polyethylene. Although the two substances have similar names, they are very different in chemical structure. The chemical molecular structure of polyethylene has strong stability and is extremely difficult to degrade, so it takes 300 years for plastic bags to decompose; while the chemical structure of polypropylene is not strong, the molecular chain can be easily broken, so it can be effectively degraded , and enter the next environmental cycle in a non-toxic form, a non-woven shopping bag can be completely decomposed within 90 days. Moreover, non-woven shopping bags can be reused more than 10 times, and the pollution to the environment after disposal is only 10% of that of plastic bags.

Disadvantage

1 Compared with woven cloth, the strength and durability are poor.

2 Cannot be washed like other fabrics.

3 The fibers are arranged in a certain direction, so it is easy to split at right angles, etc. Therefore, the improvement of the production method is mainly focused on the improvement of preventing splitting.

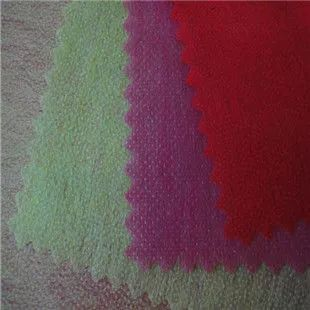

In view of these characteristics of non-woven fabrics, the cutting tools we recommend are Pneumatic Knife Tool or Driven Rotary Tool.Use a pneumatic knife to cut multiple layers, and use a Driven Rotary knife to cut a single layer。

Because the non-woven fabric has air holes, it will reduce the adsorption force of the machine, so when cutting multi-layer non-woven fabrics, it is necessary to cover the top layer with an airtight film.

Basic principles of non-woven weaving

Nonwovens are also known as nonwovens, nonwovens, nonwovens, nonwovens or nonwovens. Non-woven technology is a material processing technology that originates from textiles, but goes beyond textiles. Different non-woven process technologies have their own corresponding process principles. Generally speaking, the basic principles of non-woven technology are the same, which can be described by its technological process, which can generally be divided into the following four processes: (1) fiber preparation; (2) web formation; (3) reinforcement; (4) finishing.

Classification of non-woven fabrics

Non-woven fabrics can be divided into:

Spunlace non-woven fabric

It is to spray high-pressure fine water flow onto one or more layers of fiber webs, so that the fibers are entangled with each other, so that the fiber webs can be strengthened and have a certain strength.

Features

Flexible entanglement, does not affect the original characteristics of the fiber, and does not damage the fiber;

The appearance is closer to traditional textiles;

High strength and low fluff;

High hygroscopicity, rapid moisture absorption;

Soft hand feel and good drapability

Changeable appearance;

The production process is long and covers a large area;

Complex equipment and high water quality requirements;

High energy consumption.

Applications

Medical curtains, surgical gowns, surgical cover cloths, medical dressing materials, wound dressings, medical gauze, aviation rags, clothing lining fabrics, coated fabrics, disposable materials, high-grade rags for instruments, high-grade rags for electronics industry, towels, Cotton pads, wet wipes, mask covering materials, etc.

Heat-sealed non-woven fabric

It refers to the addition of fibrous or powdery hot-melt adhesive reinforcement materials to the fiber web, and the fiber web is then heated, melted, cooled, and consolidated into a cloth.

Features

Surface-bonded hot-rolled surfaces are mostly smooth, and point-bonded hot-rolled are relatively fluffy.

Applications

Production of baby diapers and women's sanitary napkin covering materials, ointment base cloth, tape base cloth ABD pad covering materials, clothing linings, masks, etc.

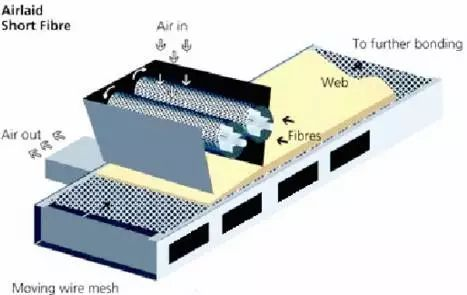

Pulp Airlaid Nonwoven

It can also be called dust-free paper and dry-laid non-woven fabric. It uses the air-laid technology to open the wood pulp fiberboard into a single fiber state, and then uses the air-laid method to condense the fibers on the web-forming curtain, and the fiber web is then reinforced into a cloth.

Features

It is characterized by good bulkiness, soft hand, wet strength and abrasion resistance. Due to the paper, it has super hygroscopic properties.

Applications

Medical hygiene materials, especially disposable hygiene products with high water absorption (such as diapers, sanitary napkins, wet gluten, wipes, etc.).

![]()

Wetlaid non-woven fabric

The fiber raw material placed in the water medium is loosened into single fibers, and different fiber raw materials are mixed at the same time to make a fiber suspension slurry.

Features

High production speed, up to 400m/min;

Can make full use of short fibers, such as length below 20mm;

There is almost no limit to the mix of fibers of different qualities;

The uniformity of the fiber web of the product is better;

Large water consumption and high one-time investment.

Applications

Special paper: dust/liquid filter paper, tea bags;

Industrial use: filters, insulating materials, sound-absorbing materials;

Medical use: medical backing, medical tape, surgical bag wrapping materials;

Civil: wallpaper, etc.

Spunbond Nonwoven

After the polymer has been extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is then subjected to self-bonding, thermal bonding, chemical bonding or mechanical reinforcement methods to make the web become spinning.

Features

The web consists of continuous filaments;

Excellent tensile strength;

There are many changes in the process, and various methods can be used for reinforcement;

Wide variation range of filament fineness;

The hand feel is poor, and the uniformity of the fiber web is poor.

Applications

Polypropylene (PP): geotextiles, tufted carpet base fabrics, coated base fabrics, medical materials, covering materials for disposable products, etc.

Polyester (PET): filter materials, lining materials, tufted carpet base fabrics, agricultural materials, packaging materials, etc.

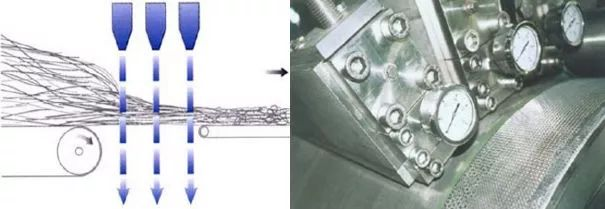

Meltblown non-woven fabric

After the polymer has been extruded and left the spinneret, the melt is blown into ultra-fine staple fibers under the action of high-speed hot air, and the speed of extruding a piece flies to the mesh, and then reinforced by thermal bonding or self-adhesion to form Non-woven.

Features

The web consists of very fine, but unconnected, shorter fibers;

The uniformity of the fiber web is good, and the hand feels soft;

Good filtration performance and liquid absorption performance;

Poor web strength.

Applications

Filter materials, medical and health materials, clothing materials, battery separator materials, wiping materials.

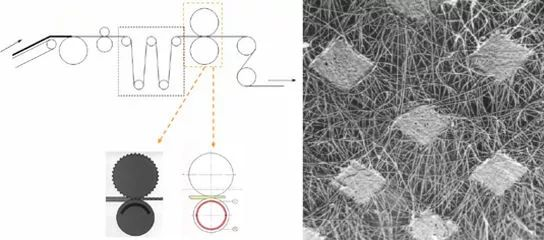

Needle Punched Nonwoven

It is a kind of dry-laid non-woven fabric. Needle-punched non-woven fabrics use the puncturing effect of thorn needles to reinforce the fluffy fiber web into cloth.

Features

Suitable for all kinds of fibers, the machine does not depend on the original characteristics of which fiber you choose after giving birth;

Does not affect the original characteristics of the fiber;

Flexible entanglement between fibers, with good dimensional stability and elasticity;

Good permeability and filtration performance;

Feel plump and fluffy;

Various collection patterns or three-dimensional molding products can be manufactured upon request.

However, the cutting speed of each material depends on the specific processing shape and the hardness of the material. If you have non-woven cutting requirements, you can send samples to us, and we will recommend the most suitable cutting plan for you according to the specific material.

No. 7 Workshop, Changruxiang Industrial Park, Yushan Road, Licheng District, Jinan Shandong

No. 7 Workshop, Changruxiang Industrial Park, Yushan Road, Licheng District, Jinan Shandong +86 18560162709

+86 18560162709 250109

250109